Services

Why INDUSTRIALE (industrial) takes place in the name of the company?

Because Ellebeta uses its industrial processes in order to guarantee compliance, continuity and qualitative standards to the production process; these features hand over the final product that has an high functionality, optimization and quality.

Let’s see how Ellebeta provides its services:

ANLAYSIS, PROGECTS MODIFICATION WITH TECHNICAL DRAWING

The expert supervision of the team composed by Ellebeta’s professionals, as a task, has to analyze the technical drawings and projects directly from the headquarter of Turin, from which, later, the informations are sent to the production technical office of the Chinese factory.

During this phase, Ellebeta, thanks to its team of specialists, can also envelope or modify the project of the client using the last 2D and 3D graphic design softwares.

EXECUTION OF EQUIPMENTS AND PATTERNS

When it’s necessary Ellebeta, cooperated by its partners, is able to make patterns and equipments for the productions of metal castings. The function of the patterns defines by types: traditional aged wooden pattern, metallic shell or synthetic material pattern (plastic or synthetic resin) and also pattern for the investment casting. However patterns for die casting precesses of aluminium and steel parts

OBTAINING OF THE ROUGH COMPONENT

Ellebeta focuses all the energies to obtain an high quality rough product. Starting with a good quality rough material, highly decreases the number of possible deformations and problems originated by the following mechanical processing. The diversification of the suppliers (foundries and carpenter’s shops, each of them with a specific specialization) let Ellebeta be able to supply a perfect high technical quality products range: sand casting, shell casting, lost wax casting, die casting and micro casting. Ellebeta supplies also components MADE BY WELDINg OR FORGING PROCESS without forget the production by standard size bars.

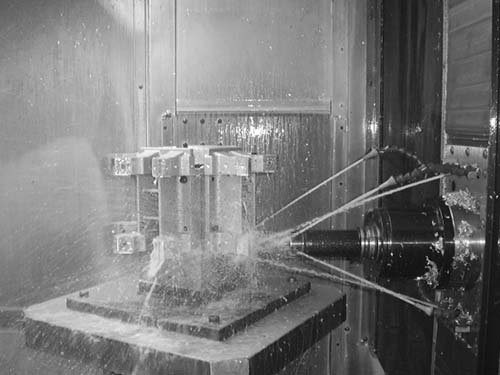

MACHINING PROCESS AND FINISHING

Ellebeta achieved an high knowledge in the machining technologies with a match of traditional mechanics methods and new technology. Nowadays the company can accomplish all the accurate mechanical processes which are made by CNC machinery.

The mechanical component, defined by drawings, is supplied after being finished in every detail, including thermal and superficial treatments.

Concerning assembled components, Ellebeta can supply the component totally assembled and ready to use.

STORAGE AND LOGISTIC

The material is packaged as the client’s request. The loading phases in China and the unloading ones in Italy are accomplished indoor so that any damage risk is avoided, ensuring a safe transport.

In order to guarantee better timings, Ellebeta manages and monitors a minimum stockpile of ready material in the office of Turin. The material is available to the customer whit 3 days deliveries “just in time” to Italy and 4 days deliveries to Europe.

CUSTOMER CARE

Ellebeta’s team takes care about every customer need, before and after the sale. The sales department team is constantly looking after the customer even after the sale for any request about order changes, state of progress and deliveries confirmation.